Move to Industry 4.0 with Coexya: business expertise, new technologies and sustainable performance at the heart of your transformation.

Why adopt Industry 4.0? Connectivity, Intelligence and Agility

The industry is facing increased demands in terms of responsiveness and quality, in a context where consumer expectations are constantly evolving and competition remains particularly intense.

To adapt, the industry is focusing on connected, digitalised and robotised factories.

The benefits are significant and measurable. According to Yannick Feillens’ book Les principes du 4.0 adaptés aux vrais besoins de votre entreprise (The principles of 4.0 tailored to the real needs of your business), a ‘reasoned’ 4.0 approach can deliver gains of 20 to 30% on at least one of the following strategic criteria: lead time, quality, cost or working capital requirements (WCR). In addition, a McKinsey study shows that the integration of Industry 4.0 technologies can lead to a 30% increase in productivity and a 15% reduction in production costs, particularly in demanding sectors such as aeronautics and automotive.

Adopting Industry 4.0 is therefore not just a technological evolution, but a major lever for competitiveness and sustainable performance for manufacturers.

A tailor-made solution for successful industrial digital transformation

We support manufacturers in their partial or total digital transformation. We analyse their needs and propose a tailored technological solution, designed based on their specifications.

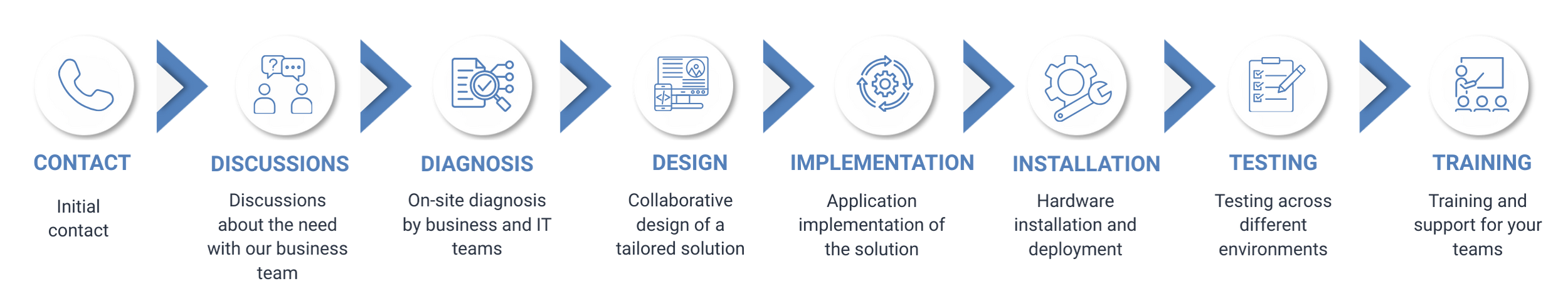

Our Industry 4.0 methodology: from audit to implementation

Industrial and technological expertise: Coexya’s strengths for Industry 4.0

A specialised team from the industrial sector, capable of taking your needs into account.

1. An experienced IT team:

- in the development and deployment of IIoT platforms

- in the implementation of applications (specific development, Web/Mobile/API, UX/UI design approach)

- in cloud computing

2. ISO27001-certified company

- Protection of sensitive industrial data

- Securing industrial systems

- Control of supply chain risks

Our commitments

Concrete examples of Industry 4.0 that we can implement: Cloud, IoT, AI

- Modular MES (Manufacturing Execution System): composed of independent and interconnectable business modules

- Modernisation of your current MES by deploying it in the Microsoft Azure cloud

- Interfacing with your internal tools (MES, ERP, CAPM, CMMS, SCADA, WMS, OPC UA, etc.) to contextualise data and exploit it through consistent indicators data becomes a decision-making tool!

- Immediate inventories thanks to IoT geolocation sensors

- Reduction in machine downtime thanks to ultra-reliable predictive maintenance based on data collected by IoT sensors and analysed using AI and machine learning

- Seamless traceability thanks to data acquisition throughout the manufacturing process and centralisation in the cloud

- Optimisation of energy consumption thanks to data collected by IoT sensors and analysed using AI