Industry 4.0 and the factory of the future: managing and improving industrial performance

How the factory becomes connected?

How is the digitalisation of the means of production revolutionising the industry?

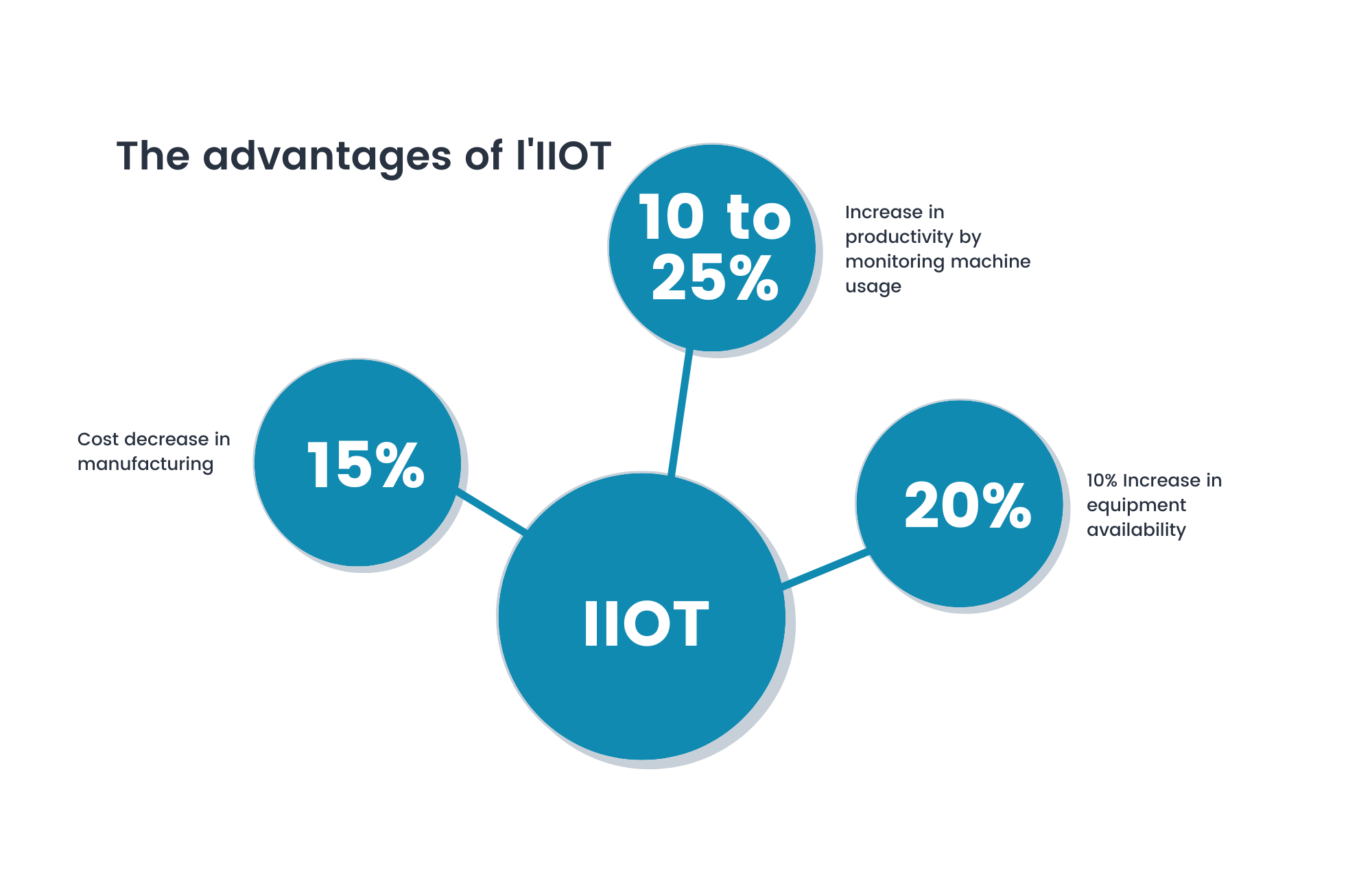

Smart industry is both a real technological challenge and a tremendous opportunity for companies. Its aim is to connect, digitalise and robotise factories.

This revolution, which makes our factories more intelligent (smart factory), is based in particular on the use of the Internet of Things. For manufacturers, it is an opportunity to adopt a more agile production system that can adapt more easily to needs while limiting or reducing costs.

New technologies, pillars of the industry of the future

The 4th industrial revolution is underway and Coexya provides technical support for your transition to the factory of the future by bringing you its dual expertise :

- Technical expertise, thanks to its team of expert consultants, all from the world of industry,

- IT expertise, thanks to our “smart data” competence centre, which assists our clients in the development and implementation of data governance.

Coexya, expert in the deployment and development of IIoT platforms

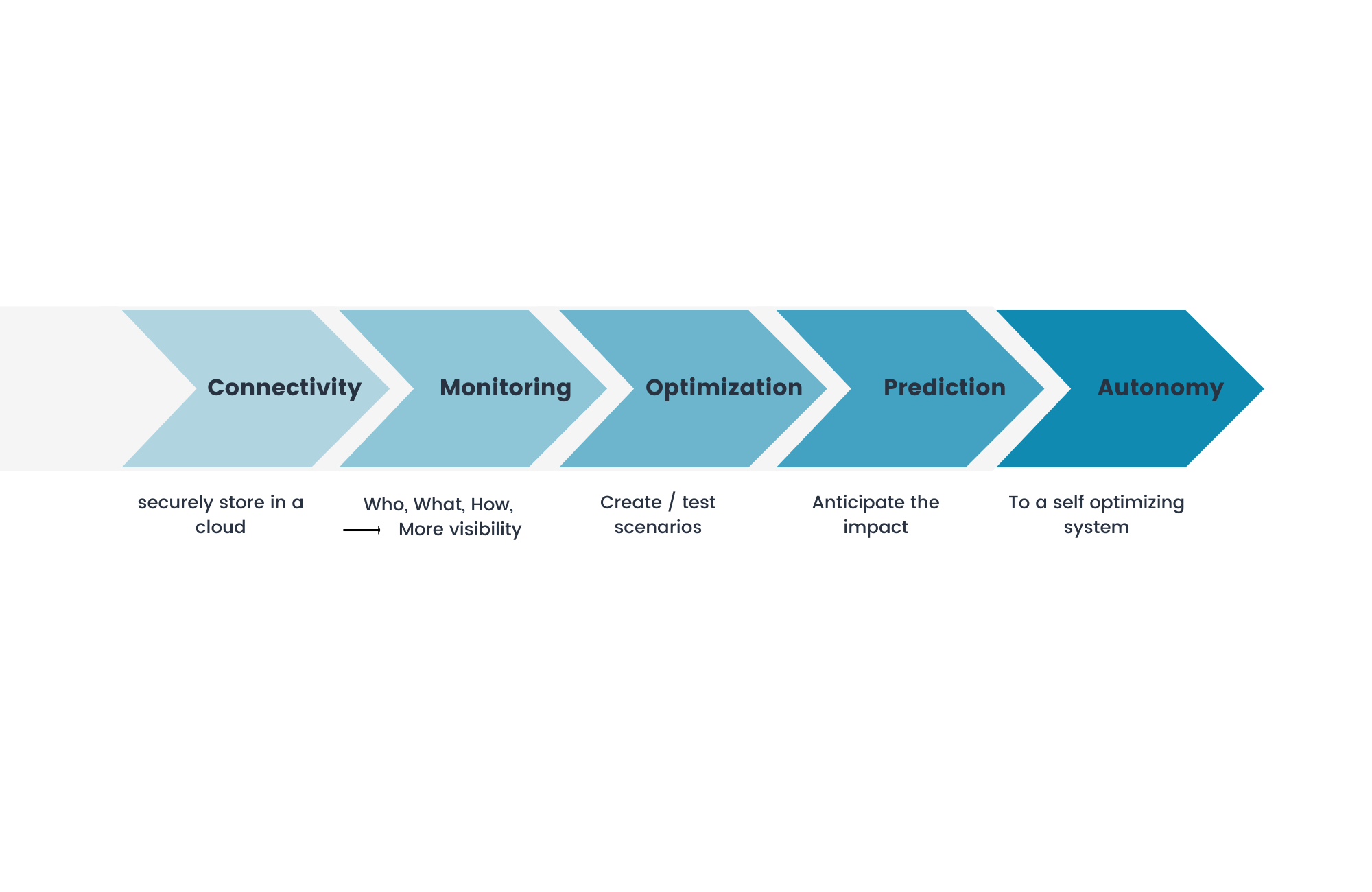

We deploy and develop Industrial Internet of Things (IIoT) platforms, designed to collect, store, analyse and visualise data that can be grafted onto your existing system and enable borderless data exploitation, regardless of where your plants are located.

Thus, in conjunction with an MES (Manufacturing Execution System) or as a replacement for it, you will be able to contextualise your data and exploit its full value thanks to the reports we provide.

Our developers, experts in industrial contexts, will help you to create applications without disrupting your production tools. And to best meet your needs, we work mainly with the market leaders: Microsoft and PTC.

To meet your needs for digitisation of production resources

A technical expertise

The Coexya group has surrounded itself with expert consultants, all of whom come from the world of industry, and who make their knowledge available to manufacturers. They have the ability to deploy platforms and applications without disrupting the operation of production tools.

An IT expertise

Our “smart data” competence centre, recognised in the field, assists its clients in the development and implementation of their data governance.

Expert support

Finally, the group advises and assists companies in drawing up their applications for subsidies, such as that proposed by the Aura region, which is aimed at SMEs and ETIs.

Discover our Azure Cloud MES offer

Boost production management with Azure Cloud managed services!

MES plays a crucial role between planning in the ERP and production resources. Having a modern component in the CIM pyramid has become essential for optimal operational efficiency. We support you in deploying this component in the Microsoft Azure cloud.

Our technological approach

We propose to build a state-of-the-art interoperable architecture at every layer:

- A custom web application interacting with a web API

- An application solution and the engine for your rules in a high-availability backend

- A data persistence system

- An integration platform as a service chain and connectors: ERP, WMS, BI, office tools, third-party clouds, etc.